Joe Tessitore is a strange guy. Most bike builders hate working with motorcycle wiring, but not Joe. It’s his favorite part of the build, and the source of most of his business. So we’ve asked Joe to demystify the motorcycle electrical system, and provide an easy tutorial guide to sparking your bike back into life.

The most overlooked, forgotten, or avoided aspect of building a custom motorcycle has to be the electrical system.

You can spend lots of time and money building a high performance engine or sculpting beautiful lines. But if there’s no spark, you just built a really nice paperweight.

That’s where the motorcycle wiring harness comes in. There are many different ways to wire your bike, but for this tutorial we’re going to assume that your factory harness is like the ones I usually find: cut, spliced, taped, cracked, and abused by countless previous owners.

We’re going to trash that one and start from scratch with a bare-bones basic harness—one that’s just enough to get you on the road, and should work for most vintage bikes.

Let’s start with the must-haves for your bike wiring:

A new modern regulator/rectifier. This takes the AC current produced by the stator and changes it to DC current to charge the battery. It will also keep the voltage from getting too high and frying your system.

Most often you can find it under the seat area or under one of the side covers. It’s a critical part of your charging system—and the easiest part to upgrade. The old ones worked poorly to begin with, and chances are, the stock one is dead or on its way out. Get a quality one from a company like Rick’s Motorsport Electrics.

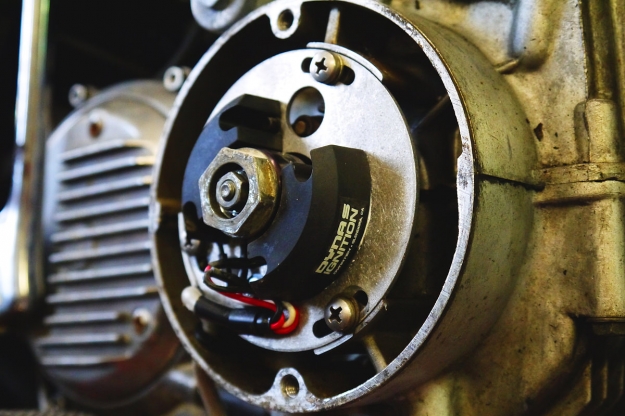

Replacing points with electronic ignitions. These send the signal to the coils telling them when to fire the spark plugs. While a traditional points ignition works fine when adjusted properly, it does require periodic maintenance and the know-how to get it dialed in just right.

For this reason many riders choose to upgrade to an electronic unit that is mostly maintenance free once installed. The most common of these are the Pamco and Dyna (below) units. They’re relatively affordable and produce great results. They also eliminate the old condensers, which often fail.

For those with larger budgets or dreams of racing there are higher end optical ignitions like Power Arc which give the most precisely timed spark for optimal power.

A brand new battery. Most street bikes won’t run without one and if the charging system was week or the bike sat for a long time, don’t take the chance. Just replace it.

Quality wire and connectors. I recommend at least 16-gauge thin stranded copper primary wire. Never use solid core made for home wiring (I’ve seen it done). Speaking of blank, nothing says “I built my bike at Home Depot and Pep Boys” like those red and blue crimp connectors. They may do the job, but if you want a professional look, go with proper supplies from Vintage Connections (below). They’ll look the part and match up to existing connectors already on your bike.

Optional goodies for the ambitious.

These aren’t completely necessary but any time you can eliminate a possible failure point in your electrical system, you’ll be ahead of the game.

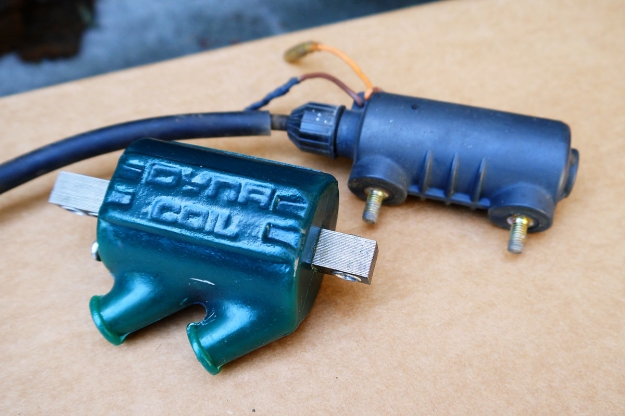

New ignition coils. These produce the power to fire the spark plugs. They’re usually found under the gas tank. Most running motorcycles still have perfectly good coils that will function well with newer electronic ignitions.

However, if your plug wires are damaged or you suspect a failure, it’s always a good idea to replace them with something new. While companies like Dyna make very good coils, I’ve had plenty of success with less expensive options like Emgo. Don’t expect aftermarket coils to match up to you stock mounts. You may have to fabricate a bracket or two but they’ll still work just fine.

Upgraded stator. The stator produces the power to run your electrical system and keep your battery charged. It’s usually under the left side cover of the engine at the end of the crankshaft. Most older machines had weak charging systems to begin with, and time has only made them worse.

If you find that upgrading the regulator/rectifier still hasn’t given you enough power, it may be time to look into this. It may not be available for all bikes but some of the more common ones like CB350s and XS650s can take advantage of offerings from Rick’s or Hugh’s Handbuilt. These units will put out a lot more charging power and in some kickstart only cases, allow you to run without a battery.

Motogadget accessories. Ah, the pièce de résistance or gold standard for motorcycle wiring. When you’ve spared no expense on your build and want a professional looking installation, Motogadget parts are the ones you reach for.

The m-Unit is a self contained, programmable, and well-labeled electrical heart for the wiring system. It uses electronic circuit breakers, making fuses obsolete. Just hook it up to your battery then run wires out to every electrical component on the bike. Headlight, taillight, turn signals, horn, the lot. There’s even an integrated alarm feature.

Definitely plug and play for someone with a little patience and a free weekend. Motogadget also offers options for electronic flashers, digital gauges, and my personal favorite, RFID keyless ignition.

Now that you have the essentials, let’s get down to business.

It’s best to think of motorcycle wiring like a circle: Power leaves the battery from one terminal, passes through whatever will use that power (lights, horn, coil, whatever), and ends up back to the opposite terminal of the battery.

If that circle is ever broken, something won’t work. Here’s the basic step-by-step:

1. Connect the negative (-) terminal of the battery to a clean, bare metal part of the frame. Preferably this would be an engine mounting point. This makes the entire frame a grounding point so every light or accessory can be grounded anywhere on the frame to complete the circle of our electric circuit. On a kickstart only bike, this can be the same size as the other wires (14-16 gauge). If using electric start, it must be much thicker (4-6 gauge).

2. Connect the positive (+) terminal to an inline fuse holder. I prefer the newer blade style over the old glass tubes, and use between 20- to 30-amp fuses.

3. From the fuse holder, we’re running a wire to your ignition switch. It can be a keyed switch or just a toggle if you’re going to hide it somewhere discreet. Either way I recommend something that will handle at least 30 amps as all power to your electrical system is running through it.

4. Now that we have a way turn the power on and off, I like to run one power wire from the front of the bike to back. I call it the backbone. Every powered accessory will tap into this wire. In this case, start with the remaining wire from ignition switch and attach it to the backbone wire.

5. Attach the hot wire from the headlight to the backbone wire and ground the other wire to the frame. Do the same with the taillight.

6. Your front and rear brake light switches each have two wires. Attach one wire to the backbone wire and the other one to the third wire on your taillight (brake light wire).

7. Your coils should have two small input wires (in most cases). Attach one from each (if you have more than one coil) to the backbone wire. The remaining wire connects to your points or chosen electronic ignition. The thick wire with the cap goes to the spark plug—but you already know that, right?

8. If you’re using electric start, connect one of the lugs of your starter solenoid to the positive (+) battery terminal with a 4-6 gauge wire. The other lug connects to the thick wire going to the starter. You also have two small wires or connector tabs on the solenoid. Connect one of these to the backbone wire and the other to your starter switch. Ground the other side of your starter switch to the frame if not already grounded through the handlebars.

9. Now for the charging system. Your new regulator/rectifier should have 3 yellow input wires. Connect these to the wires coming out of the stator (usually from the left side of the engine and the order doesn’t matter). Connect the Red wire from the reg/rec to the positive (+) battery terminal and the green wire to the negative (-) terminal.

Some bikes, like CB750s, will have an additional white field coil wire bundled with the yellow stator wires. On bikes like this, the reg/rec will have additional wires that connect to the field coil wire and powered backbone wire. Be sure to check the instructions that came with your unit.

10. That’s it! Turn the key, hit the starter button, and enjoy the sweet sound of success. You just rewired your bike!

Since this is just a basic system to get the bike running, I’ve left out things like turn signals, horn, and indicator lights. If you’d like to install these as well, just follow the same formula, power from the backbone wire, through your switch, and out to your light or accessory.

Lastly, you can wrap up your wiring masterpiece however you see fit. I like heatshrink tubing, but many people prefer to wrap using electrical tape or plastic wire looms.

Just remember to keep the wires secure and away from any sharp edges or heat sources. Broken or melted wires are the most common source of electrical failure I see.