Harley-Davidson dominates the heavyweight custom scene in Japan: many of the top builders work on no other marque. But BMW has just disrupted that paradigm with its ‘Ignite Straight 6’ project: it’s given its luxury K 1600 GTL tourer to two of Japan’s most esteemed motorcycle craftsmen.

Keiji Kawakita (Hot Dock Custom Cycles) and Kenji Nagai (Ken’s Factory) were previously Harley men to the core. So how did they handle the difficult job of customizing a machine famous for its high technology?

With the help of Japanese journalist Tadashi Kono, we decided to find out.

Keiji Kawakita opened Hot Dock Custom Cycles in 1984. He also races bikes—on the drag strip and in road races for singles and twins. He uses the experience to develop high performance parts that can also be used at the circuit, and designed the original V-twin 4-valve engine.

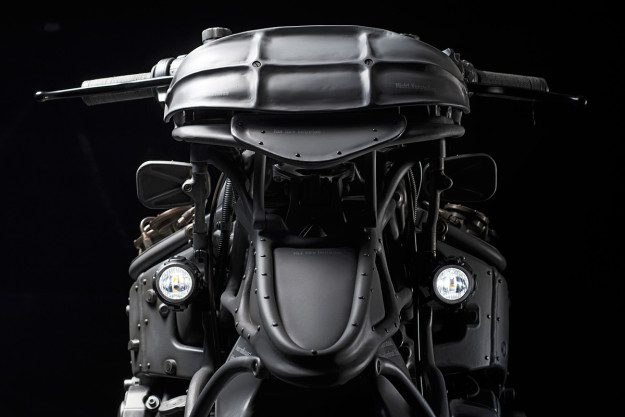

Did you find it hard to customize the bike? Yes, it far exceeded my expectations. The K 1600 GTL comes with an array of electronics—as well as the fuel injection and ABS, there is electronic suspension, ‘Adaptive Headlight,’ and grip and seat heaters. When I was told these parts were all interlinked, and so the engine would not turn on if any one of the parts were removed, I wondered, “what do I do?” My freedom to customize was restricted.

What is your usual technique? My goal when customizing is to arrange the mounted parts and the silhouette of the machine to give the bike a clean look. I seek beauty and the joy of riding—by making maximum use of minimum equipment. My opinion was that the K 1600 GTL was the opposite of this!

Where did the breakthrough come from? When I actually rode the K 1600 GTL, it was astonishingly silky. I opened the cylinder head cover with curiosity to get a look at the camshaft. Then it made sense. I could tell that the design of the engine was carefully calculated, with a focus on comfort.

So I began by tentatively removing the parts until just the engine, frame, and front fork were left. That’s when I started to struggle. I couldn’t really afford to stand around doing nothing, so I kept going. It was when the front started to take shape that the image suddenly popped into my head.

When planning a customization, do you normally design by sketching? Yes, but not this time. In a sense, bit-by-bit I cut and pasted parts to the K 1600 GTL, which had been left with only the frame, engine, and the suspension system. This was the first time I had taken such an approach.

Where did you find inspiration for the styling? About a year ago, I found a photo of a convertible car interior that was old but neo-futuristic. It inspired me to create a bike with the same sense of openness. I also had in mind a ‘future vehicle’ that might have been conceived in the early 19th century. A vehicle you might see in the film 20,000 Leagues Under the Sea.

I was thrilled to discover that a part similar to the oleo strut used on aircraft landing gears had been utilized in the Duolever area of the K 1600 GTL. Just what you would expect from a BMW. But with the standard K 1600 GTL, its large front cowl blocks the part from sight. As an aircraft fan, I was determined to make it visible.

It sounds like it was a struggle. Every day I agonized over something or the other. I would work, and then feel lost. And then get back to work. During this process I could not picture the completed bike. Even when it was done, who is to say it was really complete? But I guess that’s the nature of customization. There is no real end to it.

I had also never customized a BMW before. I was literally starting from zero. Therefore I had to rely on my past experience and my own ideas and techniques. I had to rely on myself. It’s no wonder it was so hard!

I kept the standard suspension system and frame, but all the exterior parts are handmade. I used aluminum pipes to create a mold of the exterior. Then I attached aluminum panels from the front and rear, and finished the surface.

Although the meters fitted on the exterior were dummies, I changed the design of the panels and the point of the needles to synchronize them with the surrounding parts. All non-exterior parts were coated with aging paint.

Do you have a design philosophy? I often refer to the Japanese proverb, hyotan kara koma, meaning ‘unexpected things happen.’ Even if you draw a detailed design or drawing, when you actually make something, the design could still turn out to be a failure.

After winning the top prize at the S&S Cycles “World’s Biggest Build-Off” in 2008, I lost my drive. For a while, no ideas for customization came to me. I felt like I had used up all of my ideas, and I was ready to hand the torch over to others from the younger generation.

Then the R nineT Custom Project was started. I was inspired by my juniors who were working away so hard. It looked fun, and I started to wonder what I would do if I were in their shoes. I was also shocked when I saw Lotus’s concept bike, as well as the K 1600 made by Fred Krugger. This made me acutely aware of the openness of the world of customization and the fact that the bike scene was evolving.

This was exactly when I was consulted about this project, and I accepted the offer on the spot. I wanted to make a bike that would impress the four builders who created the R nineT customs. It was a little after that I realized customizing a K 1600 base was so challenging!

But when all is said and done, I had a lot of fun. I would wake up a little earlier than usual and think, “Maybe I’ll try this today.” Every morning, these thoughts naturally ran through my head. With so many constraints, came many hardships.

But my joy outweighed the pain. I hadn’t felt like this in a long time.

Hot Dock Custom Cycles Website | Instagram

Kenji Nagai opened Ken’s Factory in 1990, and has won many awards at custom shows in Japan, Europe and the USA. He now has a shop in Long Beach, California, and sells aluminum-machined parts renowned for their quality and design.

You’re essentially a Harley builder, aren’t you? Although I’m completely devoted to customizing Harleys, I still have an interest in other bikes and their mechanisms. So I could not resist customizing BMW’s latest model.

The experience made me realize that the theories I’ve developed over the years about creating custom bikes were not true at all. This time, I spent more time thinking than I did working.

What was your first impression of the K 1600 GTL? I rode the bike about 300 kilometers from Tokyo to my shop in Nagoya. The ride was more comfortable than I thought it would be.

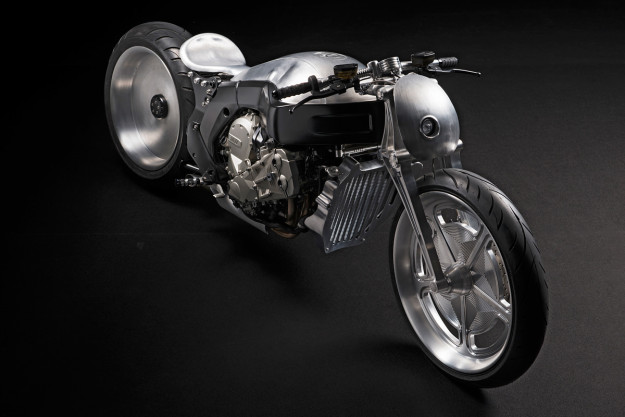

The stability and comfort of the bike in high-speed areas were superior to other touring models, and the inline six-cylinder engine is truly fascinating. As someone who loves powerful engines, I began to really want a K 1600 GTL.

How did you start work? I disassembled the exterior parts to understand the wiring and the intricate electronic control parts. I first dreamed of customizing the bike in a bagger style, to build on the bike’s tourer image. But transforming a tourer into a bagger is too mundane.

That is why I searched for a different approach. What I came up with was the ‘digger’ style: a thin, long silhouette created by laying the steering neck to its side, and extending the front fork. This gives the inline 6 cylinder engine maximum presence.

So I cut the front side of the frame and made a new one. I then fitted a Ken’s Factory brand aluminum girder fork. I measured the dimensions in standard state, and decided on the dimensions of the new neck area using the cut steering head area.

I changed the front and rear 17-inch wheels to a 23-inch front wheel and 20-inch rear wheel. I kept the exterior accessories as simple as possible.

It sounds easier said than done. Yes, it involved a series of trials and errors. I experienced more setbacks than ever before. I guess it was inevitable, since I was working with the bike for the first time—but it was truly difficult.

I could not really enjoy the production process. But when I saw the completed vehicle in front of me, I was filled with relief and realized what an interesting project it had been. I made many new discoveries that I will be able to use in my future work.

Customizing is an important part of my life. Ideas are always on my mind, whether I am soaking in the bath, having a good time, or drinking alcohol. Sometimes I take notes on my mobile phone so I won’t forget my ideas. Sometimes I forget I even took notes in the first place—that was the case this time. But the effort paid off.

We were expected to turn the K 1600 GTL into a bike that is fun, and generates a different type of excitement to the standard one. I think I was able to meet that expectation.

Ken’s Factory Website | Facebook | Instagram