Parents are always proud to see what their kids grow up to become and what kind of skills they pick up. This story isn’t about a father being proud of his daughter though; It’s about a daughter being proud of her Papa.—Sofi Tsingos

I grew up watching my Dad George build a business from the ground up—restoring old cars and motorcycles, and being ‘period correct’ on all things he did.

That all seemed normal to me and I always looked up to him for it. But I never experienced that ‘proud’ moment that parents talk about with their kids.

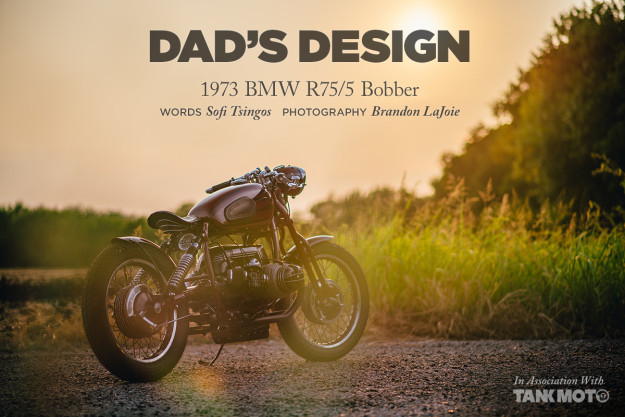

It was interesting to hear that he wanted to build a custom motorcycle. I’m not sure where his inspiration came from, but when you look at this creation it’s an almost perfect mix of cafe racer, bobber and Art Deco piece.

It was not the fastest build, because he was also helping me build GT-Moto, and working on customers’ bikes. So I never really saw what it was going to turn into, until the last couple of months. Sculpting each piece from scratch with minimal tools is proof of a true craftsman.

When he finished all the parts on the bike, he started on the paint, spending hours masking, unmasking and sketching until he was 100% happy with what he saw. It was unbelievable what this man’s brain came up with.

The bike started life as a 1973 BMW R75/5. We found it for sale in Oklahoma in a very rough, barely running condition. It had many non-original parts, so instead of restoring it, Dad decided he would do something a bit different.

He started out by checking the entire frame for straightness. He separated the neck from its mounting points and added three degrees of rake. The rear was then chopped off, custom-made shock mounts welded on, and new Hagon shocks installed.

The springer front end is a modified DNA assembly with a custom made axle, and the handlebars were scratch built—with the wiring and control cables concealed inside.

The steering damper was a bit of an experiment using custom made parts, and thankfully functions better than he’d anticipated.

The fuel tank came from a BMW R60 we found. With the air box gone, the tool compartment was modified to house the main electrical components—including an EarthX lithium battery.

The headlight bucket is an original ’60s Italian C.E.V. [made in Italy by Fratelli Pagani]. It’s been modified to carry the electronic tachometer and more of the bike’s electronics, and is mounted using a custom-formed bracket. My Dad then built the tail light from scratch using multiple LEDs for the running and brake lights.

The engine machine work was carried out by Perry Bushong in Fort Worth, Texas, and was finished off with a custom cover we built—along with the Art Deco-inspired chrome trim pieces.

There’s also an electronic ignition system that keeps it running smoothly, and the tires are Continentals mounted on the stock rims, hubs and brakes.

It’s a comfortable bike, with a seating position that means it can be ridden. Dad and I did all the design and modifications in-house, including the frame, suspension and welding. We also did the body and paint, wiring and assembly.

The powder coating was done by Patrick at Cross Link in Dallas, and the chrome by Pulido Plating of Balch Springs, Texas. The seat was stitched by Eric at Boss Hogg Custom Seats in Dallas.

It’s one thing to see a finished bike, but watching it evolve—seeing Dad’s blood and sweat go into getting it to look the way he wanted—was a whole different experience. It was my ‘proud moment.’

I remember him asking me what I thought when it was done. All I could do is hug him and tell him how proud I was that he did something so different. Not just from what I normally see him do, but from what I’ve seen anyone do with this kind of bike. He’s a genius.

Adapted with permission from the original in Tank Moto | Tank Moto Facebook | Instagram

Sofi Tsingos/GT Moto | Facebook | Instagram | Images by Brandon LaJoie