There are lots of grey areas in the custom world. The engineering on a factory bike is black-and-white in its precision: components are thoroughly tested, and they comply with a multitude of regulations. If they fail, the manufacturer could face legal action.

Unless a custom job is purely aesthetic, it’s likely to compromise this engineering. Some bolt-on mods are undoubtedly improvements, but others—especially when one-off fabrication is involved—could compromise the integrity of the machine.

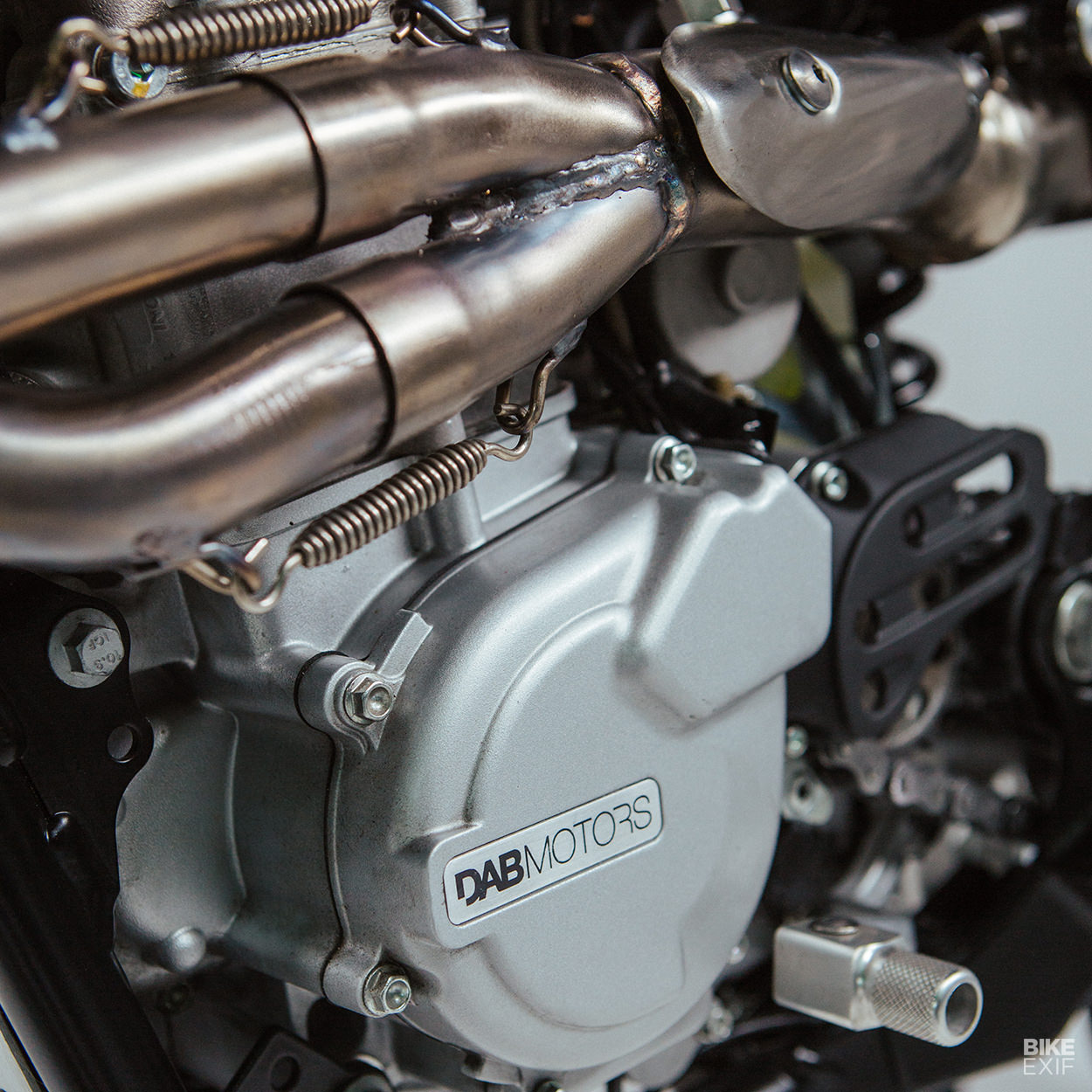

The French custom shop Dab Motors sees this as an opportunity. They’ve created the first custom motorcycle that is Euro4 certified: the LM-S. It’s also the first bike you can customize online before placing your order.

Dab was established in Biarritz in 2017 by Simon Dabadie, and for this project he’s been joined by another experienced engineer— Pierre Jayet, formerly of Peugeot. It’s a good match because both guys are passionate about 3D design technology, additive manufacturing, and cutting-edge materials.

The LM-S is a mix of urban, enduro and supermoto styles, with a minimalist ethos. It’s impressively light too, weighing just 125 kilos (275 pounds).

“It represents the simplicity and essence of a motorcycle,” Simon tells us. “A fine silhouette, light weight, a playful engine and high-end equipment. It’s the ultimate toy for custom bike passionnés.”

At the core of LM-S is the 500cc DOHC single-cylinder engine from the Husqvarna 510, chosen for its quick throttle response, light weight and power. It’s slotted into a high strength steel beam frame with a double cradle design, based on the Husqvarna 510 design, and there’s a custom-designed aluminum swingarm.

Dab have chosen adjustable 48mm Kayaba suspension both front and rear, but can upgrade this to premium Öhlins MX 48 RXF forks and a TTX shock if the budget permits.

Braking is via Brembo, and the LM-S comes with optional ABS that can be turned off and on by the rider. There’s a 320mm disc and radial four-piston caliper at the front, and a 240mm disc and floating caliper at the back.

The 17-inch wheels have been developed by SM Pro, using hubs CNC machined out of 7116 aluminum. The spokes are stainless steel and attach via anodized nipples for longevity.

The ancillary parts are all top drawer, from the Motogadget Mini speedo and blinkers to the Renthal bars and Biltwell grips. Rizoma helped with the design of the cap that sits on the Euro4-certifed 7.5-liter (2 gallon) tank.

So far, so good. But it was the Euro4 certification that caused the biggest headaches for Simon and Pierre, and almost brought the project to its knees. It’s even harder than getting a notorious TÜV pass, because the list includes emissions tests, evaporative tests, electromagnetic compatibility tests, sound level tests, braking tests, lighting quality, and an inspection to check production processes.

“The homologation department came to the Dab Motors HQ to check that we could control and improve the quality of our production,” Simon explains. “After months of work on the LM-S and our manufacturing process, we finally went to Italy for the homologation.”

The boys left Biarritz with a van full of spare parts, tools, and measurement equipment. They had to prepare the bike with multiple mounts for sensors. “We are not going to lie: we were sad when we saw that we had to damage our hard work to weld sensors everywhere, but this is how it‘s done.”

The procedure started with a test to verify that the LM-S was not emitting too much electromagnetic emission. The second test was for emissions, and the laboratory simulated riding cycles on a dyno to mimic riding conditions from urban to highway. Then the lab destroyed three gas tanks, and cut one in half.

“The final days were more relaxed,” Simon recalls. “We verified the braking, lighting and smaller details, which was less stressful.”

The upside is that LM-S can be legally sold throughout Europe and buyers won’t have to worry about the bike failing an inspection or being turned away on importation.

The upside is that LM-S can be legally sold throughout Europe and buyers won’t have to worry about the bike failing an inspection or being turned away on importation.

Even better, Dab have an online configurator on their website, allowing customers to mix and match components and finishes before placing an order.

It’s a high tech approach, but one we’re probably going to see a lot more of. “In a world driven by technology, we don‘t have to be stuck in the old

ways of working,” says Simon.

“It’s about opening your mind to revolutionary ways of doing things: 3D design, virtual engineering, 3D simulation, and rendering. This will change how we create and customize a motorcycle.”

Much as we love grinders and English wheels, we think Simon’s right.

Dab Motors | Facebook | Instagram | 3D artist: Alexey Afanasyev | Images by CAPSUS / Guilhem Machenaud / Yannick Marrot