A year ago, we revealed Diamond Atelier’s new ‘Mark II’ series of BMW café racers. Based on the classic R-series, the Mark II was designed to use parts produced in batches, rather than as one-offs. A ‘production custom,’ if you will.

Twelve months on, and the Mark II is thriving. The Munich-based company reports 20 units sold since they kicked off the first build, with bikes being delivered as far as Seoul.

In fact, the lads reckon they’ve got a Mark II on every continent already. And that’s not counting offshoot builds that use some—but not all—of the Mark II parts. So we figured it was about time to check in how things were going.

The gorgeous machines you see here are the latest Mark IIs to roll off the line. And while they’re visually close to the bikes we revealed last year, Diamond have made a number of improvements—and learnt a few lessons along the way.

Each bike starts out as a 1980s model BMW boxer motor and Monolever frame, favored for its single-sided swing arm. Diamond rebuilds and refurbishes the engine and carbs if necessary, before kitting the bike out with their signature Mark II tank, tail and subframe.

The tail section’s one of the cleanest we’ve seen, with a CAD-designed subframe hiding inside the bodywork to create a floating effect. What’s more, it meets with Germany’s notoriously strict TÜV standard.

A ‘Stage 1’ Mark II comes with refurbished OEM suspension and wheels, but a ‘Stage 3’ comes kitted with upgraded components. Those include a custom 17” wheel set with Tokico calipers, and upside down forks built around Marzocchi legs, Yamaha R1 axles and custom-machined triples. And there’s a Wilbers shock, set up specifically for each rider.

Each Mark II is sporting a number of subtler details too. There’s a lot of wiring work on each bike, a new exhaust system, and all the usual bits like lighting and controls. Some of these can be picked according to the customer’s preference—along with the paint job. And one of these Mark II’s also feature Diamond’s latest offering: carbon fiber bodywork.

We touched base with the Diamond Atelier team, to gain some insight into what’s been happening over the last year.

EXIF: What distinguishes these Mark II’s from the first batch? Diamond Atelier: A lot. The first bikes were prototypes. Even though we were very confident that they all work and function fine, we did not have any long-term experience with this small series. But already when building the first set back then, we made notes on what to improve next time.

If you build a bike once and come up with an improvement too late, you have a hard time implementing it afterwards. But with a series like this, we can do exactly this the next time around.

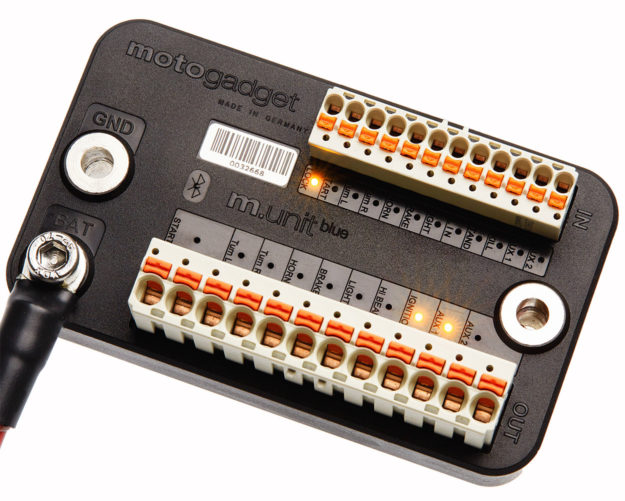

Can you give us an example of something you changed? One of the major parts—not necessarily visible, but crucial—was the entire electronics system. On the prototypes we did everything ourselves…and I mean it. The only components we bought were relays, the rest was produced in-house. Even though we had total control over the process, it was very nerve wrecking to squeeze everything in such a tight spot underneath the gas tank.

So we teamed up with Motogadget, who supplied us with a bunch of their brand new M-Units [below], as they replace close to all other components, and—most importantly—run electric fuses. This way the operation on the bike is super easy, and through the Bluetooth connection to your smartphone, you can track all kinds of relevant info of your bike. It’s an option many clients choose to go with.

How about your process—how’s that changed? We’ve reworked nearly every part that we have industrially made for us. Either reinforcing it additionally where necessary, or slimming it down if possible. There have been all kinds of changes that made the assembly process easier, and the disassembly as well.

Just minor things, like specific pieces that were held down with a handful of screws before, now work just fine with less than half of them. It might sound silly, but we reevaluated each and every piece on the bike before ordering ten more, for the easiest approach possible.

Any other notable changes? A more noticeable change was the wheel set, where we now offer a 4.25 wide rim in the back (as opposed to the already large 4.00 from before), with a center spoked design for less offset.

Also we offer two types of forks (a higher and lower version) which then fit taller or shorter riders, and given the Wilbers back suspension is completely custom made anyways, we can perfectly match the rider’s individual needs.

And we found that some people prefer street tires over semi slicks, so we teamed up with Bridgestone for a few sets of their brand new Battalax T41R compound as another option.

Tell us more about these new carbon parts… The carbon fiber bike is a Mark II V2 in a way. It was an experiment from the beginning, as nobody could tell how the carbon fiber pieces would turn out when reassembling the Mark II shape.

The shapes and proportions are identical to the standard Mark II, but the process to get there was a lot ‘tougher,’ to put it politely. It is completely made from dry carbon and then covered in a coat of clear resin, which is polished to the effect shown in the pictures.

The main difference here is, that the regular fiberglass composite pieces are just ‘thrown’ into the molds and then shaped with resin. After that, the excess material is scraped off and put into shape. It does not necessarily look nice raw, but once you paint it, it doesn’t matter. But not with the carbon fiber. If you look closely, the single fibers of the carbon weave are perfectly aligned to by symmetrical to the center of the bike.

This is the result of hours and hours of handiwork from somebody who knows his craft. I must admit that we were very impressed by the result when unpacking the finished pieces. The same goes for the seat cowling and the transmission cover.

What about the ‘regular’ fiberglass parts—are those the same as before? It’s the same mold, yet the material is different. The fiberglass is lighter and more rigid due to a different compound resin. But the carbon fiber is a whole new weave. All the seat pan bases are now made from carbon fiber too, due to higher rigidity when upholstering the seat.

Any other advancements on the ‘V2’? The Mark II V2 also runs a new exhaust option that we will be offering for our builds from now—a stainless steel two-in-one-in-two setup, with the necessary legal add-ons, such as E-Marks and other TÜV shenanigans. It is a little quieter than the regular option (which I personally prefer), but better complements the original Boxer sound.

How long does it take to construct a Mark II, from order to delivery? It mainly depends on when you order. We don’t just build each bike by itself, but build the entire batch in one go to use the most synergies. This means we start the build of bikes which are not even sold yet up to the point, where individual wishes need to be taken into account.

Also the series runs next to our daily business of unique DA# builds and is affected by our waiting period for a start. All this combined took around one year for the very first bike from start to finish. But the last few lucky buyers could get their hands on a almost completed Mark II, with merely a few weeks until completion.

So, do you have a cache of donor bikes sitting in storage? Given that we build the bikes in groups, we need to purchase all at once ideally and then start them all at the same time. This naturally is a lot easier said than done, but I think we did just fine with the Mark II.

Finding solid airheads now is close to impossible in Europe. We have an agent scouting for the vehicles internationally, since we only use donors with a clean title, a trackable history and low miles. But lately these are extremely hard to come by.

In the future we might look into other donors though, since the shortage and resulting prices of the boxers are becoming ridiculous.

Any challenges along the way? Absolutely. We discovered that many suppliers in our network who we’ve been working with successfully in the past on unique builds, were simply caught off guard by the increase of production volume that we requested basically overnight.

Sometimes we needed to relocate the capacities elsewhere, sometimes we just needed to wait longer. We made sure that waiting periods were never due to our own fault, but in the end this doesn’t matter to the end client.

Especially the wheel sets, which are one of our unique selling points on the series, were a wait with almost no end, since they are at the top of the complexity list. But we also found out which suppliers took the challenge and did the best from it, which is especially important for us to know when we further expand our series offers.

The same goes for the back office work that comes with a wave of new clients, all at the same time. One of the major learnings we took from the Mark II is, that preparation is everything.

Now that we’ve further increased our service, decreased waiting periods and become stronger than ever, we are set for a new season of custom motorcycling in 2018.

Photos by Lukas Magerl.