Honda has a long-standing tradition of building middleweight bikes that are highly capable but visually dull. The mid-2000s Honda CB600F Hornet is a prime example. It makes just under 100 hp, handles well, and boasts Honda’s legendary reliability… but it’s ugly.

We don’t see a whole lot of custom Honda Hornets, which is a real shame. The punchy four-cylinder naked has tons of potential—if you know how to massage it into shape.

This custom 2006-model Honda CB600F Hornet (known as the Honda 599 in the US) comes from Francis Von Tuto in Florence, Italy. Francis is no stranger to older Japanese sportbikes, so he came into the project with a clear idea of how to take it from bland to beautiful. But before he could bring this custom Honda Hornet to life, he had to get his client on board.

From the client’s perspective, the project had been off to a rocky start. He’d originally given the bike over to a different custom builder—a good friend of Francis’ who specializes in performance bikes and manages a WorldSBK race team. But, due to unforeseen circumstances, the workshop never got further than stripping the bike.

Francis was called in to take the project over. The client agreed, but he was understandably frustrated at the prospect of having to explain all his ideas to a brand-new workshop. But one look at Francis’ portfolio set his mind at ease, and the two slowly started building a rapport.

“He initially had ideas that didn’t really match the style of the build, or in some cases that would compromise the rideability,” says Francis. “In many cases, it doesn’t help when you look for inspiration on the internet, since people post everything from six-figure builds to unrideable showpieces. It’s sometimes difficult for the average user to tell the difference.”

“After a few mock-ups and meetings, we found a way to straighten things out. Let me say this is nothing uncommon, it happens more than you would expect… and I get it! Luckily in the end we found a compromise and it all started to make sense.”

“One of the downsides of the Honda CB600F Hornet, apart from its terribly long and tall rear frame section, is its voluminous tank. But the owner wanted to keep it—so first I had to create a new design to work around it. That meant the exhaust, dash, and headlight all had to go, and the whole rear section had to be shorter and narrower, but still comfortable for a pillion.”

Francis started by reworking the Hornet’s subframe; a chore in itself. The OEM subframe is a rectangular tube affair that was designed to be hidden under bodywork—but the redesign was going to leave it exposed. So Francis cut the end off, did some judicious de-tabbing, and welded in a new rear loop, fabricated from round tubing.

Extra care was taken to ensure that the new setup wouldn’t affect the rear suspension geometry, and that there would still be room to squeeze a passenger on. Next, Francis shaped a seat pan out of fiberglass, then handed it over to BF Tappezzerie, an auto upholsterer in Florence, to finish it. It now wears double-density foam and a vinyl cover, with stitching details that were requested by the owner.

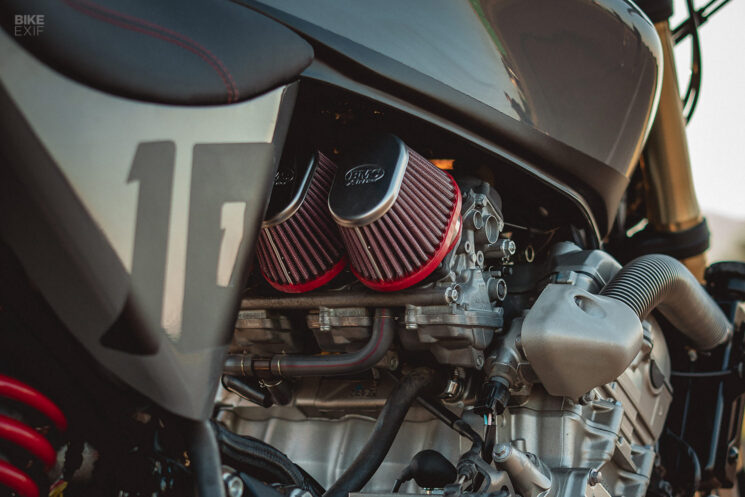

Lower down, Francis ditched the Hornet’s airbox to slim it down more. Alloy side panels now flank the bike, wrapping around the remnants of the rectangular subframe for a more cohesive aesthetic. Hiding behind the side panels are a Lithium-ion battery, a coolant reservoir, and the essential electrical bits.

A row of filters from BMC handle intake duties, with red bases that match the other red accents on the bike. Francis also installed a stage three performance kit from Dynojet, to make sure that the bike runs smoothly with the open filters.

The Hornet’s upside-down forks and 17” alloy wheels were retained, but the forks needed a rebuild. A chic sculpted fender sits above the front wheel; it looks like it’s been borrowed from a modern sportbike, but Francis actually shaped it out of aluminum using an English wheel, a hammer, and a sheet roller.

The bike’s owner supplied a new LED headlight, but the rest of the cockpit’s layout was up to Francis. He installed the light on aluminum stays, then added a laser-cut fly screen above it. A laser-cut dashboard sits flush with the screen and hosts a digital Motogadget speedo, while low-rise handlebars and bar-end mirrors complete the package.

Since the bike needed to be street-legal and somewhat practical, Francis needed to create a few extra pieces to dress the rear. A fiberglass hugger keeps muck away from the rear shock, while laser-cut stainless steel brackets hold the license plate, bolted to new CNC-machined chain adjuster plates. There’s a custom-made chain guard back there too.

Highsider LED turn signals do duty up front, with three-in-one Highsider items doubling up as turn signals and taillights at the back. The Hornet’s finished off with a pair of gnarly stainless steel mufflers, hooked up to the OEM headers via a custom connector pipe.

The Hornet’s owner wanted his bike to match his Jeep, so that took the guesswork out of picking a color. The livery needed a few small details though, so Francis enlisted the help of a friend—an illustrator who operates as The Junkers—to create a few renders. In the end, all the design needed was numbers on the side panels, a hint of black along the bottom of the tank, and classic Honda logos.

“I owe him,” says Francis, “because he hates this kind of work and never does it. So the fact that he did it for me is a big plus!”

Like everything on this custom Honda Hornet, the livery is simple, tasteful, and striking. It’s proof that the vanilla donor bike has oodles of potential—and that Francis knows how to extract that potential.

Francis Von Tuto | Facebook | Instagram | Images by Rafael Montañes Ruiz | Francis would like to thank Aero Club Serristori and Etruria Volo