With all the marketing hype around ‘adventure riding’ these days, many motorcyclists won’t dare go off the beaten track without a large capacity dual-sport, an array of aftermarket parts and a support vehicle. It’s easy to forget that there was a time when this wasn’t an option—and that it’s possible to see the world without blowing a budget worthy of a reality TV series.

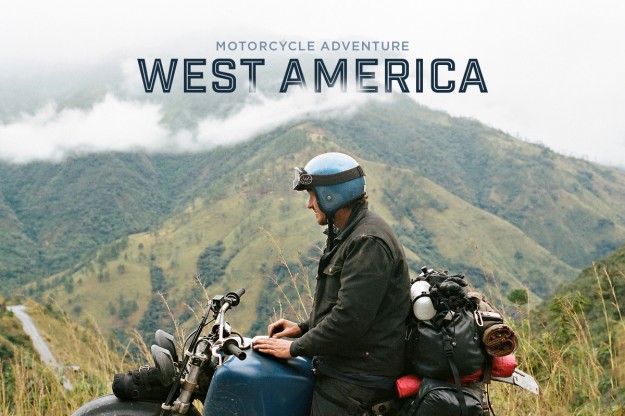

Thankfully there’s a growing contingent of people that realise this, and choose to plan their adventures with a more pragmatic mindset. Enter James Crowe and Jordan Hufnagel. Under the monikers Crowe Metal Co. and Hufnagel Cycles, they build custom motorcycles and bicycles respectively. Collectively they’re known as West America—and are currently riding two hand-built Honda XR600Rs north-to-south across the Americas.

These might not be the type of bikes you’d expect to see on Bike EXIF, but they are worthy of sharing. Partly because they’re great examples of function trumping form, but mainly because we’re envious of (and inspired by) James and Jordan’s epic journey.

“Three years ago my shop mate Jordan Hufnagel and I found ourselves living a life of routine,” explains James. “All day every day in the shop, summers slipped away and winters were long. Things finally reached a boiling point. We were both building and creating things that inspired us, but the balance was off.”

“We needed a change and the decision was made to put everything on hold and focus all our efforts on building a pair of motorcycles to ride from Whistler, BC to the southern tip of South America. I left my shop in Portland and headed back home to Canada to work on the oil rigs for the summer. It allowed me to return with enough money to take eight months off to build the bikes.”

The pair chose Honda’s legendary XR600R for a number of reasons: it’s bulletproof, easy to work on and has remained relatively unchanged since the late 80s—so parts can be found just about anywhere. The steel frame is also easier to modify (and repair along the way if necessary), and the big single makes ample power for lugging around gear. James sourced three mid-90s XRs: two plated ones and a third, unplated parts donor bike.

“Before cutting into the bikes we spent the summer of 2011 blasting around Oregon and northern California trying to figure out what changes were needed. The list was pretty basic. Stronger subframes, more gas, more comfort and good solid luggage mounting.”

For the tanks James started with foam mock ups, before making a wooden buck and shaping them out of 19 gauge steel—making them durable and easy to repair with basic welding equipment if needed. Each tank holds 7 gallons and incorporates a raised air intake through the center, with a pre-filter at the top to keep the main air filter clean. “The snorkels allow no worries on river crossings and I have only had to clean the main filter four times since leaving Canada. We clean the pre-filters as needed, but it only takes a minute.”

James also modified the subframes, moving the vertical supports further back and using thicker tubing for strength. He then fabricated luggage racks for the top and sides, to accommodate Wolfman dry bags and a 1.5-gallon auxiliary fuel tank. The total fuel range for each bike is now around 400 miles on pavement. “Even with seven gallons of fuel we have had to buy our fair share of barrel gas in remote areas of Peru,” says James. “The bikes even ran fine on the 84 octane up in the Andes. In Patagonia we have been filling both the main and aux tanks, allowing us to explore all the back roads that most have to skip.”

Shorter, wider and thicker seats were made and sent to Ginger at New Church Moto for upholstery. Up front, James installed his own wide scrambler bars, dual Hella headlamps and small, hand-made racks to hold tool rolls and tubes.

Once the fabrication was complete the bikes were tested for a month, before the engines were completely stripped and rebuilt from the crank up. Most of the transmission and rotating assembly had to be replaced. James also sourced new barrels, had them refurbished and fitted them with low-compression pistons, before sending the heads to Baisley Hi-Performance in Portland to be rebuilt.

“I bolted them up with a thicker copper head gasket to bring compression down for the poor fuel we would be encountering. Otherwise I left as much stock as possible, since the bikes are going to get dropped and banged up non-stop.” For an extra boost, FMF mufflers were fitted to the stock Honda headers.

When I last heard from them, James and Jordan were deep into Patagonia, Chile with over 13,000 miles behind them. How have the bikes performed? “Knock on wood, but all has been good.”

As for their experience, James had this to say: “Time away from the shop has allowed us to realize what’s important in life, and we are both very motivated to get back to work. Long days on the bike have had me dreaming of the next build.”

“At the end of the month we hope to be as far south as we can ride, then we will be pointed back north for the ride home. Jordan will most likely ship out of Santiago, Chile while I will continue north to Bolivia and back into Peru, making my way to Columbia.”

We wish James and Jordan all the best on the last leg of their journey.

Photos by James Crowe and Jordan Hufnagel, shot on film and scanned.