Custom motorcycles come in all shapes and sizes. But the more style variations a custom shop adds to their portfolio, the more they run the risk of watering down their work. This is not the case for Kaichiroh Kurosu, better known as Cherry’s Company.

Kurosu-san not only does it all, but he does it at the highest level too. From sportbikes to choppers, we’ve watched him produce consistently stunning work, year on year. And he’s even able to blend multiple styles into a single bike; no wonder he’s one of the leading lights of the Japanese custom scene.

His latest project, ‘Midnight Dancer,’ started out as the unlikeliest of donors: a 2008 BMW HP2 Sport. If you’re unfamiliar, the HP2 Sport was a hardcore sportbike with full carbon bodywork, putting out a claimed 130 hp and weighing in at 397 lbs dry. At the time, it was the lightest and fastest boxer BMW had ever produced.

Costing around $26,000 when it was new, and highly collectable now, the HP2 Sport is not a bike people are generally lining up to chop. But this one had been in an accident—leaving the bodywork wrecked, but the chassis and running gear intact. The choice was clear, and the bike was brought to Cherry’s Company for a makeover.

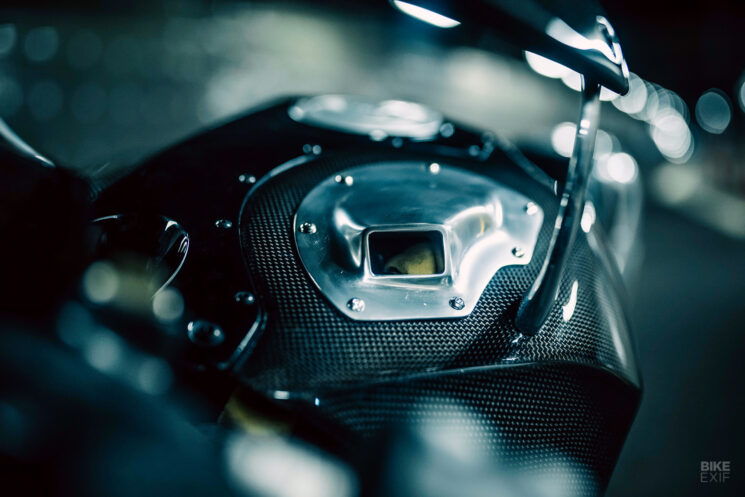

Since the donor bike was originally wrapped in carbon fiber, Kaichiroh felt compelled to execute his custom work in carbon too. He’d been using the lightweight material on his made-to-order ‘Highway Fighter’ BMW R nineT builds, but those kits were laid up by hand. In search of a better method, Kaichiroh discovered Vacuum Infusion Technology.

We won’t get into the technical details, but the end result is parts that are higher quality and stronger than hand-laid pieces. And the process allows for forms and shapes not otherwise possible, freeing up new possibilities in design.

“When I exhibited the Midnight Dancer at the Yokohama Hot Rod Custom Show, many journalists asked me why I used a carbon exterior,” Kaichiroh tells us. “It seems that they felt that the hot rod scene and carbon parts, or resin parts for that matter, were not a good fit for each other.”

“However, the hot rod scene has been customizing with resin parts since the 1960s, exemplified by Tracy Nelson’s Fiberglas Works custom bikes with their one-piece fiberglass bodies. And now, more than 50 years on, even the aging of Tracy’s custom bikes, with their chipped fibers and faded paint, is part of the customization process, I guess.”

Once the production method was established, design could begin. The initial idea was to build an 80s-style Grand Prix bike with a large fairing and somewhat exaggerated proportions—at least compared to the GP bikes of today.

Kaichiroh intentionally went for a design with overlapping parts. That allowed him to build his new fairing and fuel tank section over the BMW’s original inner fuel reservoir, and to use the existing mounting points. He even included an aluminum intake just behind the fairing, to direct air into the stock airbox.

Carbon fiber was also used to create new fenders, and an extensive belly pan. But when it came to the tail section, Kaichiroh changed tack. “I was going to finish the rear cowl in carbon too,” he explains, “but during the production process I started to think that I wanted a style that combines metal and carbon.”

“Even nowadays, MotoGP or WSBK race bikes sometimes use aluminum as-is only for their fuel tanks. In the off-season, when no sponsor or livery has been decided on, the racing teams test bikes with an aluminum tank, which is raw, and a carbon cowl. And it’s cool.”

The bare metal creates a stark contrast agains the mostly-black HP2 Sport. The only paint comes in the form of gold leaf scrollwork around the fairing, fender, and gas tank shroud, adding a bit of show and finish. Look closely, and you’ll also spot fresh nickel plating on the frame.

Smaller details include a custom license plate holder at the rear, an aluminum surround for the headlights, and aluminum fairing braces that connect to the tank cover.

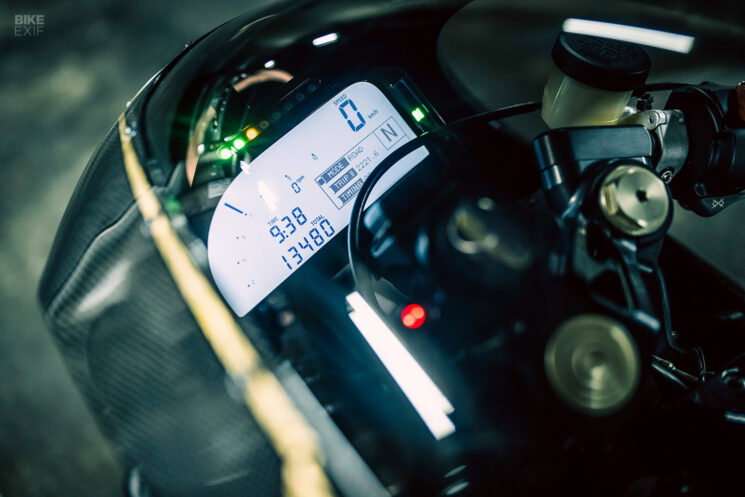

The HP2 Sport came from the factory with forged aluminum wheels, top-spec Brembo brakes, and Öhlins shocks mounted to its telelever front and paralever rear suspension. Kaichiroh wisely left that all one, along with the stock digital components, adding only a fresh set of Michelin Power Cup 2 tires.

A final touch comes via the custom exhaust silencer. The HP2 Sport’s stock unit is usually mounted just below the rear cowl; here, it’s hidden inside it.

The combination of BMW engineering and reimagined HP2 components, with Kaichiroh’s sculptural vision and the contrasting finishes, is completely transformative. The final product is a machine that is still, 25 years later, performing at a very high level—but now looks like something only Cherry’s Company could produce.

Cherry’s Company | Facebook | Instagram | Images by Hiromitsu Yasui | With thanks to Tadashi Kono