Harley-Davidson has just launched two new Sportsters: the Iron 1200 and the Forty-Eight Special. Both have throwback styling and graphics to commemorate the Motor Company’s 115th anniversary, but don’t offer anything mechanically different.

We’re betting that there’s a completely new Sportster model in the Milwaukee engineering pipeline right now. But we’ve also had 14 years to appreciate the current Sportster’s strength: it’s been customized in so many ways, there’s a ton of parts—and inspiration—out there. Which was the premise for one of the strangest gigs I’ve ever attended as a moto journalist.

Harley-Davidson know this well. So they invited a select bunch of journalists and web celebs to their hometown to participate in the ‘Brewtown Throwdown.’ Four teams would be given three weeks to plan and two days to build up different Sportster models, with the finished bikes displayed at the Mama Tried show.

My team was given the new Iron 1200 to customize. Out the box it’s a chopper-esque mash up; high in front, low in the back, with mini-ape bars, a nose fairing, and a gorgeous period-correct AMF graphic on the tank.

H-D’s marketing crew obviously has a sense of humor, because they asked us to turn the Iron 1200 into a cafe racer. So we had to radically change not only the Iron’s trim, but also its stance. And we weren’t allowed to swap or modify the new tank in any way.

We were also given a budget for parts, and our parts list had to have a specific percentage split between H-D and third party parts. And although we could arrange for paint and fabrication to be completed before we touched down in Milwaukee, the final teardown and assembly had to happen over the two days before Mama Tried.

My team was an interesting mix of folks, to put it mildly. We had Harley’s engine calibration engineer Nerissa Cerny, a couple of guys from a meme website called The Chive, an Austrian-born fitness model and YouTuber called Johannes Bartl, and his wingman Phi Nguyen.

Harley’s marketing guy Kyle Brown was on hand to make sure we didn’t do anything stupid. And since we were based in the showroom of a local dealer called Uke’s Harley-Davidson, their mechanics Rob Voss and Billy Lobacz helped out as wrenches-slash-mentors.

With less than three weeks to prep, we all jumped onto Skype to get ideas onto the table. Design by committee can be tough, but the folks on our team knew when to campaign for an idea and when to compromise. And Rob’s knowledge as Uke’s parts and accessories guy was invaluable in keeping us on track.

Our ultimate goal was to sort the Iron 1200’s lines and stance, and choose parts and mods that would be quick and easy to execute. The Burly Brand cafe tail section was a no brainer—the shape’s just right, and it’s a straight bolt-on part.

We wanted to raise the rear end too, so we played with the idea of scavenging a set of Street Rod piggyback shocks. But they didn’t quite give us the lift we needed, so we settled on 15” Stilettos from Burly Brand, and decided to drop the front by an inch.

Then we had to pick a bigger rear wheel to balance things out. Rob wedged a 19” in the rear at first, but we eventually settled on an 18” Roadster rear wheel.

Since we couldn’t mod the tank, we were stuck with the hunched fly line that the Sporty has. But as our concept evolved, this inspired a more muscular, modern look—which in turn informed our last few parts choices.

At first, we were looking at classic headlight options, but thanks to Johannes and Phi’s input we shifted to a smoked Plexiglas number board with LED spots. (We even managed to source one that bolts right onto the Sporty, saving us time). Then we added bits like a belly spoiler to give the Iron 1200 a bit more race flavor.

We knew the Iron 1200 would spend most of its time at shows, but we still wanted to build something that would be rad to ride. Clip-ons and rear-sets were a must for tightening up the ergonomics and satisfying the brief.

A Bassani two-into-one exhaust and a completely open velocity stack matched the overall aesthetic perfectly. And yes, an open stack is completely impractical. But watching that butterfly open and close is hypnotic—and we can always switch it for something better if the bike ever sees road use.

It was a no-brainer to carry the colors of that sweet AMF graphic through to the rest of the build, but we were wary of overdoing it. So we matched the stripes on the tail, and opted to keep most of the rest of the bike blacked out. As for the wheels, we took cues from the supermotard world and designed them in white, with blue accents.

A few rough Photoshop mockups and emails later, and our design was nailed down. As I packed my bags to fly from South Africa to the States, the crew from Uke’s ordered parts and tackled the fabrication and paint.

Uke’s Harley-Davidson is a family business, owned by Keith and Nance Ulicki and based in Kenosha, just outside Milwaukee. Keith’s father opened the dealership in 1930, and throughout the build, Keith and Nance couldn’t contain their excitement. They truly are warm, passionate and genuine people.

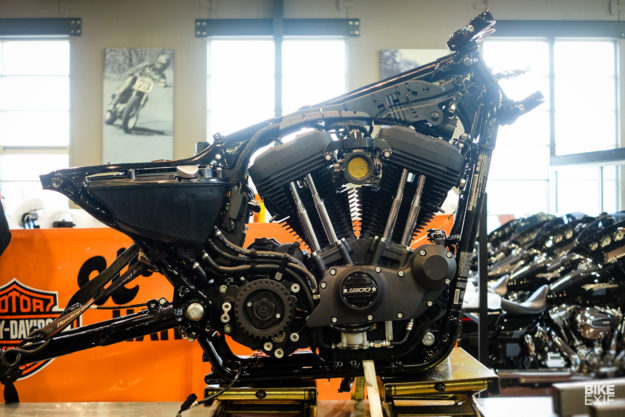

Rob and Billy set up our ‘workshop’ in the middle of the showroom floor, dragging a bike lift, toolboxes and rolling shelves up from their actual workshop. As soon as we were good to go, everyone grabbed a tool and started yanking parts off, until just the frame, motor, swing arm, forks and wiring remained.

Then it was time to check out the pre-fab work. The struts had been cut and cleaned up neatly, and the forks had been dropped internally. But there were subtler touches that took a while to spot.

The guys knew we wanted to ramp up performance and were planning to ditch the sprocket cover. So they executed an old Harley race mod and trimmed the right side engine cover of all excess metal to save weight. They also axed the ABS, saving more weight and ditching a bunch of ugly wires in the process.

Over the next two days, we gradually built the Iron 1200 back up, transforming it into the café racer we’d been imagining for the past few weeks. Everyone got their hands dirty—even The Chive’s Chase and Doug. They admitted that they were out of their element but that didn’t hold them back.

Watching something you’ve helped design materialize is a crazy, exciting feeling. For me, the standout moment was seeing the new shocks, repainted wheels and clip-ons fitted. The Iron 1200’s aggressive new stance was coming together. And watching old-school Harley dudes wander into the showroom and check out the weird cafe racer on the lift was just as cool.

Miraculously—or thanks to Rob and Billy’s meticulous prep work—everything went according to plan. Just one mod appeared on the fly. We weren’t digging the pegs and peg brackets that came with the rear sets, so we modified the brackets to accept the sharper, shorter stock pegs.

As we neared completion, Uke’s had a couple more surprises for us. Rob had asked us to let him handle the taillight, and he revealed a LED Harley Bar and Shield under a dark Plexiglas window molded into the tail hump. With the bike done, Keith casually wandered over and planted a pair of one-off Uke’s dice valve caps on the wheels.

Despite the extreme constraints on time and money and the tight brief, we all got on with each other, had a laugh, and felt like we’d ticked every box. Except one.

Firing a new bike up for the first time should be a highlight. But with a completely open velocity stack, all that came out of the exhaust was an uneven splutter.

Luckily Nerissa deals with this every day, and she’d anticipated the problem. Earlier in the week, she sneaked the exhaust and stack back to HQ, installed them on another Sportster, and mapped out a custom engine tune.

Our bike might not be practical for daily riding with that velocity stack on, but it runs great now. And it screams.

After much back and forth with legal (and a long wait for the tarmac to dry up), we wheeled the Iron 1200 into the parking lot for photos and a few laps around the dealership. I’m stoked with how it turned out—not only for the new lines, stance and color scheme, but also for how much fun it is to ride.

The only down side is that I’ll probably never swing a leg over it again. But if I can find a Sporty and a little cash to play with, I’ll be able to recreate this from memory. If nothing else, this project has proven the Sportster’s status as a true blank canvas for custom work.

Harley-Davidson | Facebook | Instagram | Images by Josh Kurpius and Wes Reyneke

Parts list

H-D clip ons

H-D rear sets, modified

H-D speedo lowering bracket

Free Spirits Sportster-specific bolt-on number board / headlight combo, with custom vinyl

Stock speedo casing trimmed to interface with number board

Front forks dropped 1”, internally

Stock Sportster Iron 1200 front wheel, repainted

Sportster Roadster 18” rear wheel, repainted

Pirelli Angel GT rear tire

Burly Brand café tail section

Burly Brand 15” Stiletto rear shocks, lower springs painted white

H-D oil tank dipstick bezel, black

H-D pop-up fuel cap, black

Right side engine cover trim

Sprocket cover removed, front sprocket and parts painted wrinkle black

Lower tappet covers painted wrinkle black

Rear sprocket painted white on the front, black on the back

H-D belly pan spoiler

H-D XR1200 side stand

ABS removal

Trimmed stock front fender

Uke’s one-off dice valve caps

Custom Bar and Shield LED tail light

Chromed steel velocity stack

Bassani two-into-one stainless steel exhaust

Custom engine tune

Side cover graphics, including Keith Ulicki’s race number: 73

Paint by Custom Painted Vehicles

Thanks to Harley-Davidson for making this happen.