When Jeff Lamb contacted us about his ‘MZ Special,’ we thought we’d just stumbled upon a new shop, specializing in vintage, racing-inspired customs. But we were dead wrong.

It turns out that Jeff’s just a regular bloke: “I’m a 41-year-old hopeless motorcycle enthusiast, now amateur bike builder, from Brisbane, Australia. A self-employed father of two boys, husband of a great woman and owner of some tools.”

A couple of years ago Jeff met the Ellaspede crew at a moto expo. By the end of the conversation, Jeff knew he wanted a cafe racer. All he needed was a suitable donor, and that’s where the bizarre—and surprisingly capable—MZ Skorpion comes in.

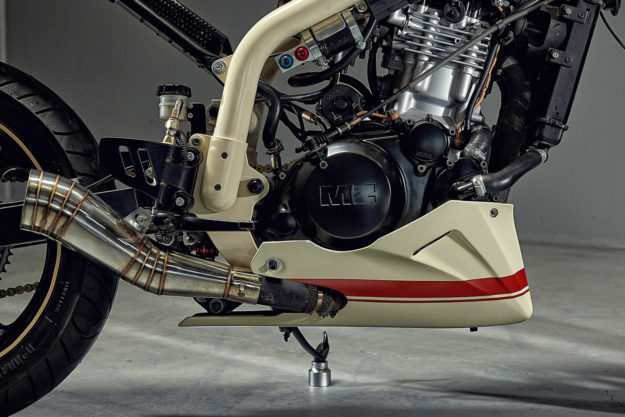

Launched in 1994, the Skorpion featured a British chassis, Italian brakes and suspension, and a Japanese engine and electrics—borrowed from the Yamaha XT660. Everything was assembled at MZ’s home base in Germany.

It sounds like the world’s worst parts-bin special, but the press at the time praised it for being affordable and light, with heaps of torque and good handling. It also became a popular choice for club racing, even if it was a curious-looking machine.

“The large-diameter-tube perimeter frame was a real standout—I hadn’t seen anything like it before,” says Jeff. “It reminded me of the frames of 1960s Puch scooters and mopeds.”

Sold on the idea, Jeff snapped up a 99-model Skorpion Tour, “with no shortage of Blu-Tack, touch up paint, electrical tape, cable ties, hope and WD-40.”

There was just one problem: despite having a ton of ideas originally, Jeff hit a creative wall. After countless sketches and false starts, he finally stripped the bike down out of sheer desperation.

“I now had hundreds of parts, more ideas, a bike that wasn’t usable, a mess and more builder’s block. This didn’t really help.”

Jeff threw in the towel, loaded up a trailer with all the parts and made his way to Ellaspede’s workshop. Ideas were exchanged, sketches made and emails sent back and forth. A clear brief was soon on the table.

“They costed the job based on my dreams,” says Jeff, “and that’s when I learned what it costs to have a pro shop take a concept through to reality. I paid the guys for the work to date, picked up my trailer full of bits and licked my wounds.”

“The gap between my ideas and the reality of a full custom build was a mix of shock and disappointment—not in Ellaspede, but in myself for thinking this sort of thing can be done for a small amount of money.”

At least Jeff now had a clear direction. So he decided to do as much as he could himself, outsource whatever was beyond his means—and bring Ellaspede back in near the end.

First on the agenda was sorting out the fairing. An Avon-style fairing was key to what Jeff had in mind, so he contacted a well-known classic fiberglass manufacturer who claimed to have the right molds.

“But when it came to me offering an order and an up-front payment,” explains Jeff, “it became a trail of unanswered phone calls and emails. Eventually the internet coughed one up, and this one made its way, ironically, from Germany.”

Next up was the one-piece fuel tank, seat unit and rear oil tank. Jeff shaped the whole unit out of foam, before handing it over to a local fabricator. More hiccups ensued…

“He thought he could do it, but couldn’t bring himself to tell me (or himself) he couldn’t,” says Jeff. “For seven months the mold and frame were with him, and it took me fronting him to come clean to get the gear back.”

“In a twist, a friend randomly suggested I try a place he drives past regularly, which brought me to a chap called John Allen, fabricator extraordinaire. His story is fascinating on its own: ex-Honda Factory rider form the 80s and early 90s, former room-mate of Kevin Schwantz and current racer of a TZ750 two-stroke missile at post-classic racing meets. And a just nice, modest bloke.”

John knocked it out the park, fabricating everything to Jeff’s spec while adding all the reinforcing needed to make it work properly. “To think his life and incredible motorcycle experience brought that tank unit to my bike, is actually humbling.”

In the meantime, Jeff had been busy with smaller details. Every part was cleaned, refreshed, painted, polished or replaced, right down to the last bolt. “Wynnum Bearings and Bolts were invaluable help,” says Jeff.

He also built the seat pan—by heating 10mm thick commercial grade kitchen cutting board in the oven, and fitting it to the bodywork. Once it was perfect, he sent it off for some professional upholstery.

The finish on the new levers is equally homemade. Jeff wrapped them in leather, dipped them in epoxy, then refined the shape with an angle grinder before a final dip. “The end result feels good, offers nice grip and was good fun!”

Off-the-shelf parts include CNC’ed clip-ons, minimal Posh switches and a lobster-tail exhaust. The forks are stock Paioli units that Jeff sent to Rad Hard Chroming to rebuild and re-chrome. They even carry new, vintage Paioli stickers, tucked safely under a clear coat.

There’s a new, adjustable Wilbers shock out back too. John helped relocate the rear brake reservoir with a new frame mount. The ignition was relocated, so Jeff sourced an MZ clock to fill the hole left in the triple clamp. “It worked… once.”

The belly pan took three goes, finally working when Jeff got an early 2000s Yamaha part to fit as intended. The paint saw Jeff cycling through vendors again, until Roberto’s Custom Powder Coating hit the mark.

Then Ellaspede re-entered the picture. “I had some ideas for the gauges that I couldn’t make happen and Ellaspede came to the rescue with a neat and functional Acewell gauge. It was good to know the team were still on board when I needed them.”

Ellaspede finished Jeff’s electrical work for him—including making a new wiring harness—sorted out a few issues, handled some additional fabrication and even sorted out a breather issue with the relocated oil tank.

They also tackled the final fire-up, test and tune, finally helping Jeff and his ‘MZ Special’ over the finish line.

Jeff admits that, in the end, he probably didn’t save any money going this route. But he learnt a hell of a lot along the way.

“People like John Allen and Ellaspede are an example of the depth of skill that exists out there in motorcycle land,” he says. “But for every John Allen there seem to be a few dreamers who take on jobs they are not up to.”

“Advice in some of the custom Facebook groups is brilliant, even if just for inspiration or motivation. Members of the FB groups Brisbane Café Racers and Sydney Café Racers have contributed, without probably even knowing it.”

He adds that he owes a debt of gratitude to his long-suffering wife, Kendell, and to his brother, Chris, for his motivation.

But what we really want to know, is would he do it again? “Yes, and I’ve already started on a super rare Honda MVX250—a two stroke V3.”

Here’s hoping things go a little more smoothly next time.

Images by AJ Moller.